APKR 100308PDR-HP IC840

High positive inserts for machining stainless steel and high temperature alloys

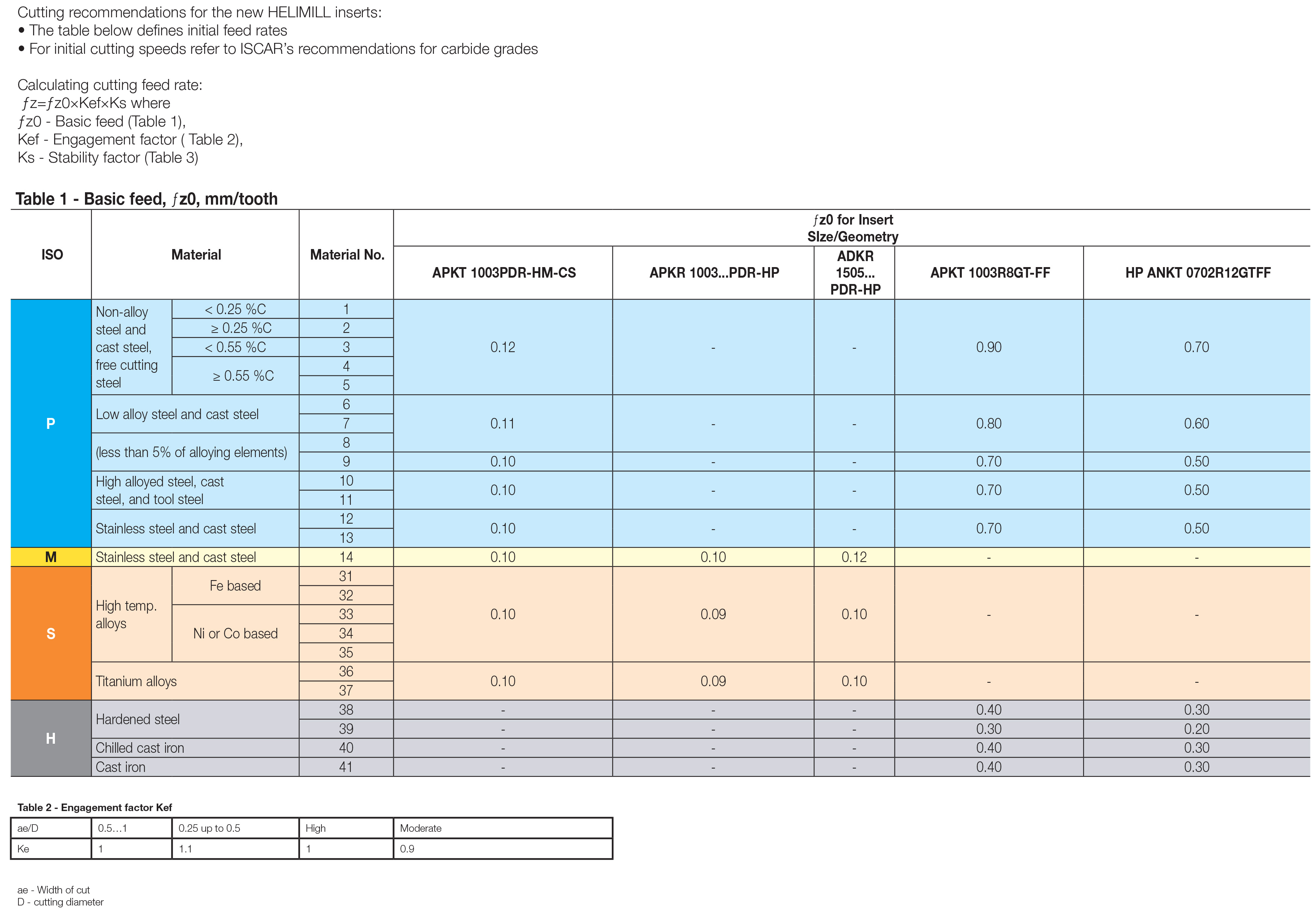

| Applicable Material | | Stainless Steel | Super-Alloys / Titanium | | Maximum Feed per Tooth (fz(max)) | 0.15 mm/tooth |

| Application | | Countersinking | Drill Mill | Facing | Plunging & Recessing | Rampdown | Shouldering | Slanted Shoulder & Chamfer | Slotting | | Cutting Edge Material | Carbide |

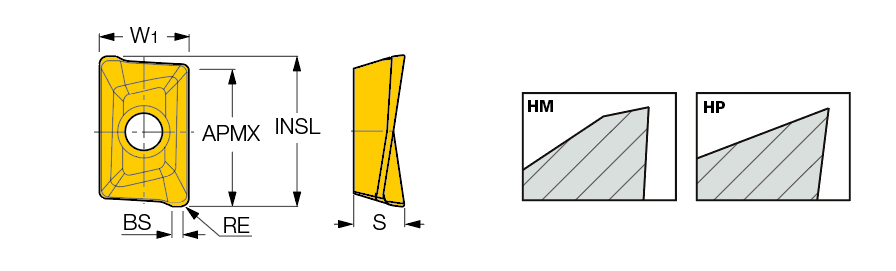

| Insert Length (INSL) | 11.5 mm | Tool Type | Mill AL, HTA Geometric Inserts |

| Corner Radius (RE) | 0.8 mm | Minimum Feed per Tooth (fz(min)) | 0.07 mm/tooth |

| Depth of Cut Maximum (APMX) | 9.8 mm | Number of Cutting Edges | 2 |

| Insert Width (W1) | 6.7 mm | Cutting Edge Effective Length (LE) | 10.3 mm |

| Insert Thickness (S) | 3.8 mm | Measurement Type | Metric |

| Coating | AlTiN+TiAlSiN+TiSiN | Body Material | Carbide |

| Grade | IC840 | Unit | M |

Product Features

| Family Description | High positive inserts for machining stainless steel and high temperature alloys | FamilyName | APKR 1003PDR |

| COO | Israel | BrandName | Iscar |

Shipping Info

Weight per item

0.0034

Name

Milling Indexable Inserts

FamilyName

APKR 1003PDR

BrandName

Iscar

Related Items

Item successfully added to your cart

Items successfully added to your cart

Added to

Go to My Lists

Select List

Change Quantity?